Comprehensive Guide to Hazardous Waste Management for Semiconductor Solutions

Understanding Hazardous Waste in the Semiconductor Industry

The semiconductor industry plays a critical role in the advancement of technology. However, it also generates a significant amount of hazardous waste. This waste includes chemicals, solvents, and materials used in the manufacturing process that pose serious environmental and health risks if not managed properly. Understanding the nature of these wastes is the first step in mitigating their impact.

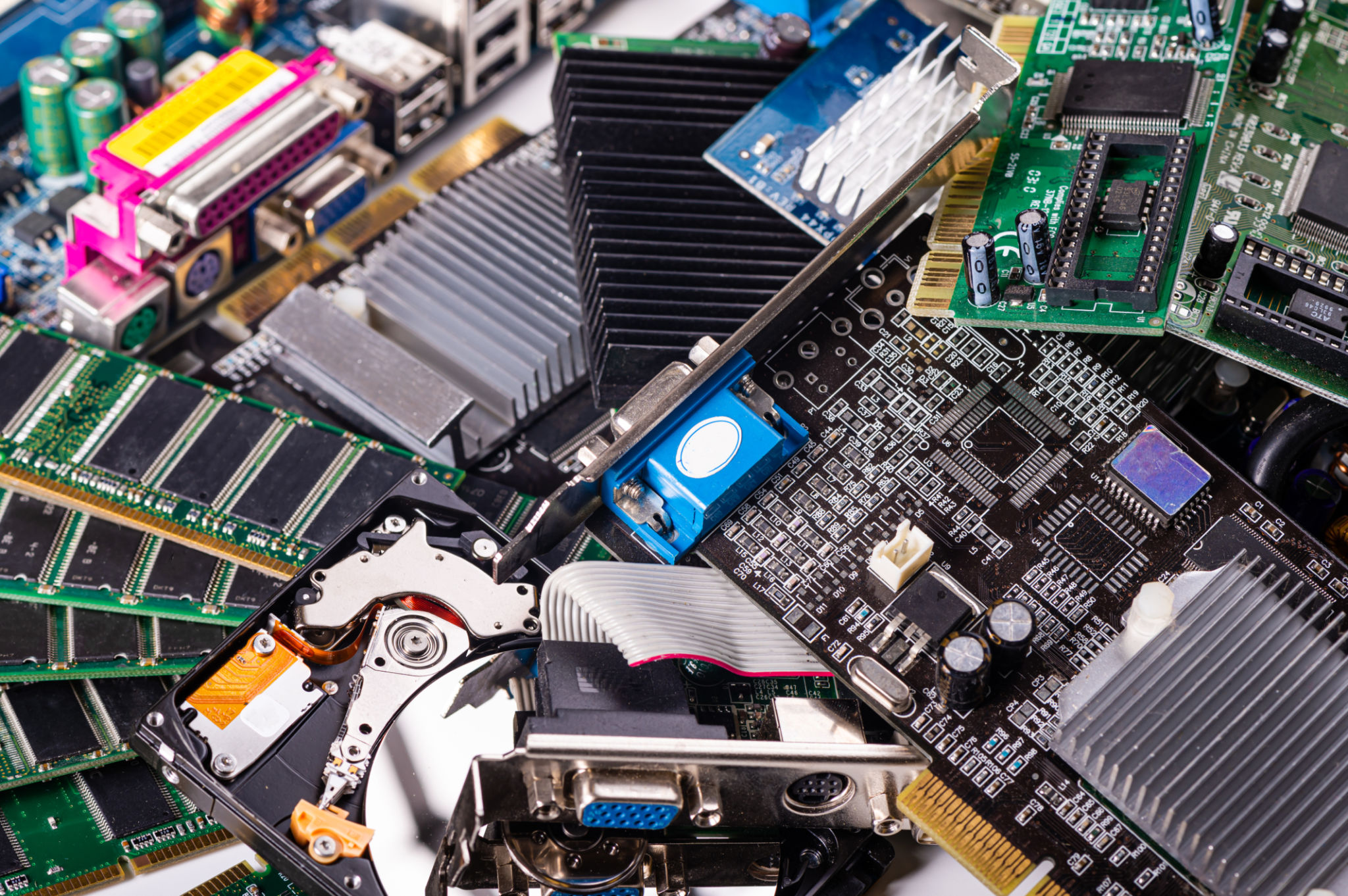

Types of Hazardous Waste Generated

Semiconductor manufacturing involves various processes that produce different types of hazardous waste. These can be broadly categorized into chemical wastes, heavy metals, and electronic waste. Each category requires specific handling and disposal methods to ensure safety and compliance with environmental regulations.

Chemical Waste

Chemical waste includes acids, bases, solvents, and other reactive substances used in the etching and cleaning processes. These chemicals can be harmful to both human health and the environment if not disposed of correctly. Proper containment and disposal are essential to prevent leaks and contamination.

Heavy Metals

Heavy metals such as lead, cadmium, and mercury are often found in semiconductor manufacturing waste. These elements are highly toxic and can have long-lasting effects on ecosystems. Special attention is required to recycle or dispose of materials containing these metals safely.

Regulatory Compliance and Standards

Adhering to regulatory standards is crucial for semiconductor companies to manage hazardous waste effectively. Organizations must comply with local, national, and international laws governing waste management. This includes obtaining necessary permits, maintaining records, and following best practices for storage, transportation, and disposal.

Environmental Protection Agency (EPA) Guidelines

In the United States, the EPA sets forth guidelines and regulations under the Resource Conservation and Recovery Act (RCRA) that dictate how hazardous waste should be managed. Companies must familiarize themselves with these regulations to ensure their waste management practices are compliant.

Strategies for Hazardous Waste Management

Effective hazardous waste management in the semiconductor industry involves several strategies aimed at minimizing waste generation and ensuring safe disposal. These strategies not only protect the environment but also contribute to sustainable business practices.

Waste Minimization Techniques

Reducing the amount of hazardous waste generated is a key objective. This can be achieved through process optimization, substitution of less harmful materials, and recycling efforts. Implementing these techniques helps in reducing the overall environmental footprint of semiconductor manufacturing.

Safe Disposal Practices

Proper disposal of hazardous waste is essential to prevent environmental contamination. Companies should work with certified disposal facilities that adhere to strict guidelines for handling toxic materials. Additionally, continuous monitoring and audits are necessary to ensure compliance with all safety standards.

The Role of Technology in Waste Management

Advancements in technology provide new opportunities for improving hazardous waste management. Automation, real-time monitoring systems, and data analytics can enhance the efficiency and effectiveness of waste management processes. These technologies help in identifying potential risks and optimizing waste handling procedures.

Innovative Solutions

Innovative solutions such as chemical recycling, advanced filtration systems, and AI-driven waste analysis are transforming how the semiconductor industry manages its hazardous waste. These innovations not only improve safety but also offer cost savings by reducing waste disposal expenses.

In conclusion, comprehensive hazardous waste management is vital for the semiconductor industry to operate sustainably. By understanding the types of waste generated, adhering to regulations, implementing effective strategies, and leveraging technology, companies can significantly mitigate their environmental impact while maintaining operational efficiency.